LEAK TESTER WITH INTEGRATED DATA AUTOMATION

Fully Automated Leak Tester

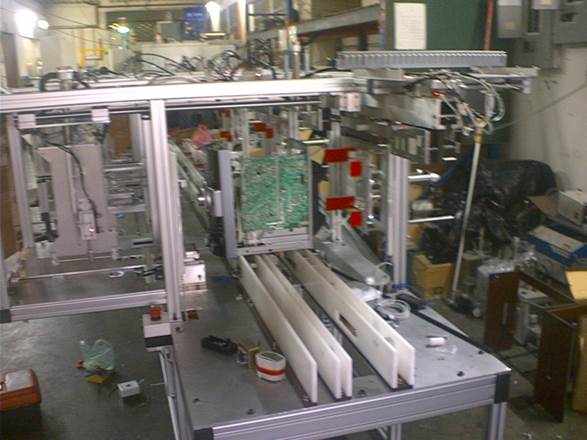

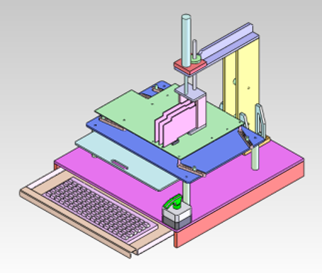

AUTOMATED CONVEYORIZED TESTING SOLUTION

Modularized Conveyor System

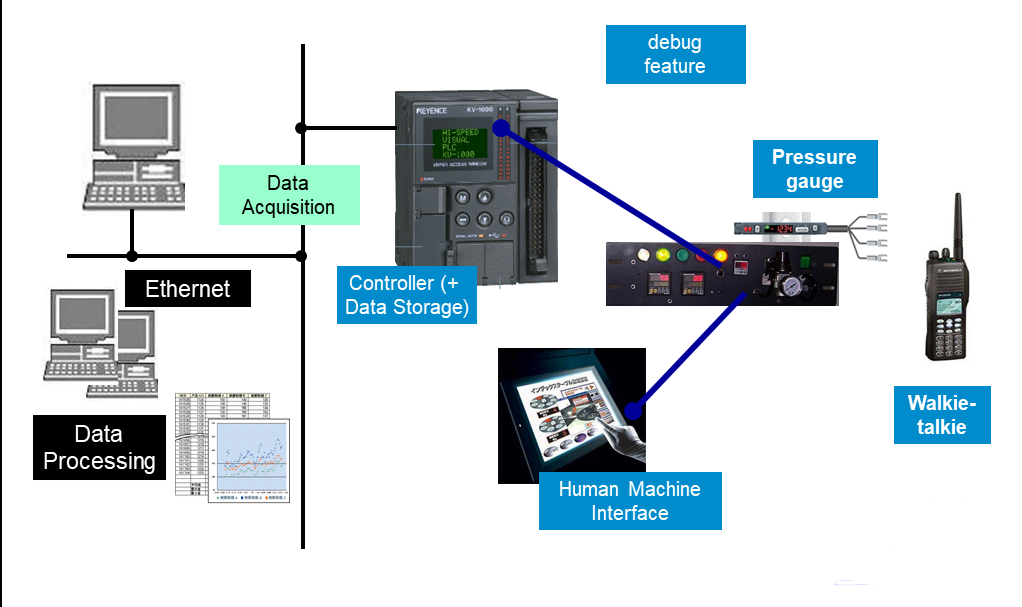

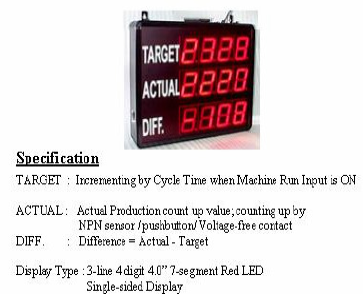

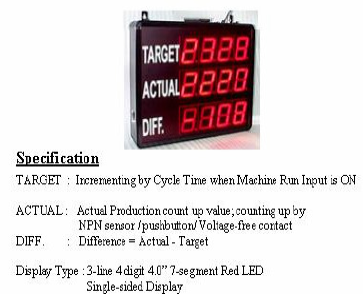

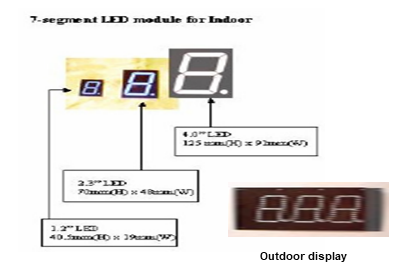

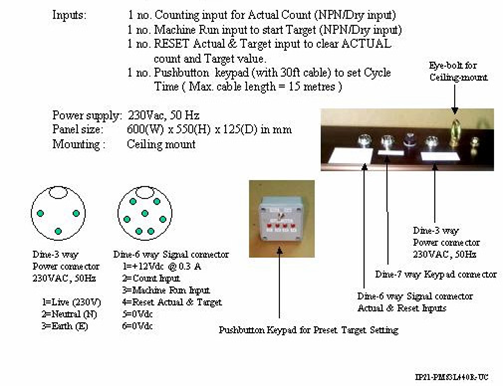

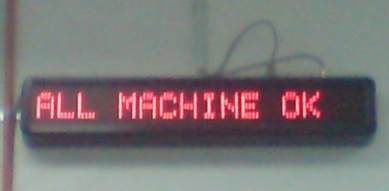

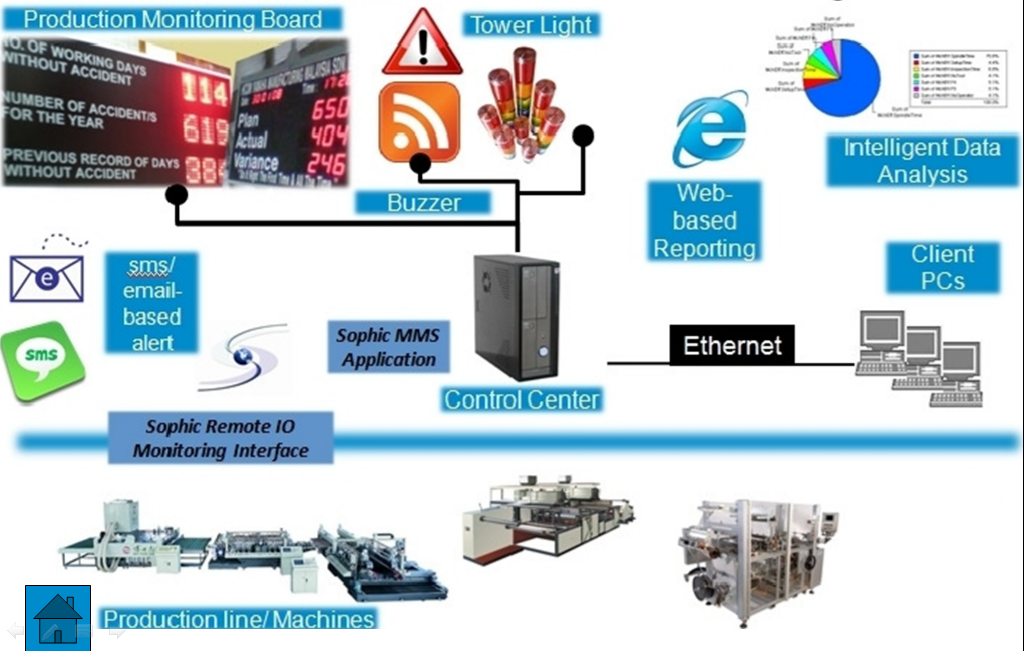

MACHINE MONITORING SYSTEM

Machine Monitoring System

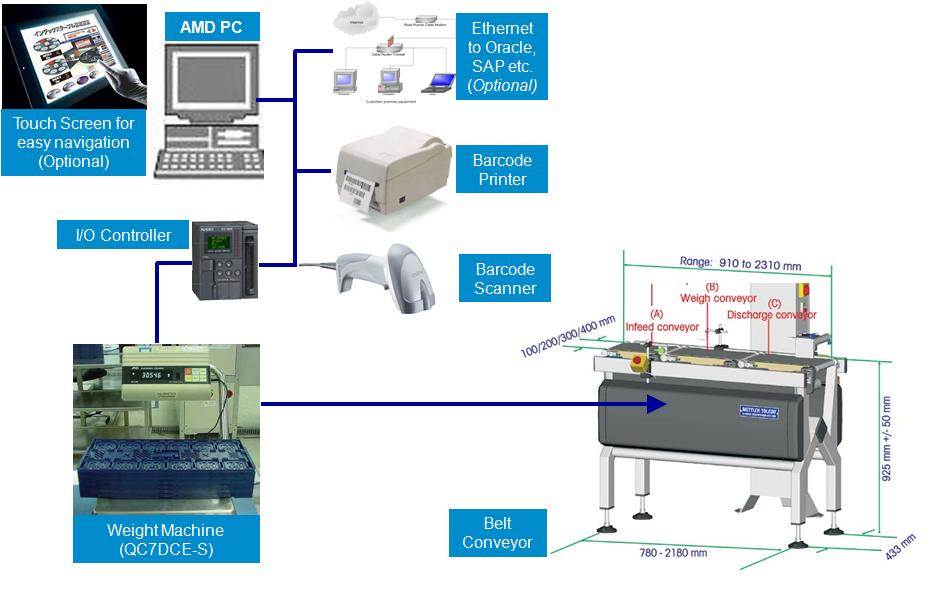

TRACEBILITY SOLUTION FOR CHECK_WEIGHER

Weight Machine (QC7DCE-S)

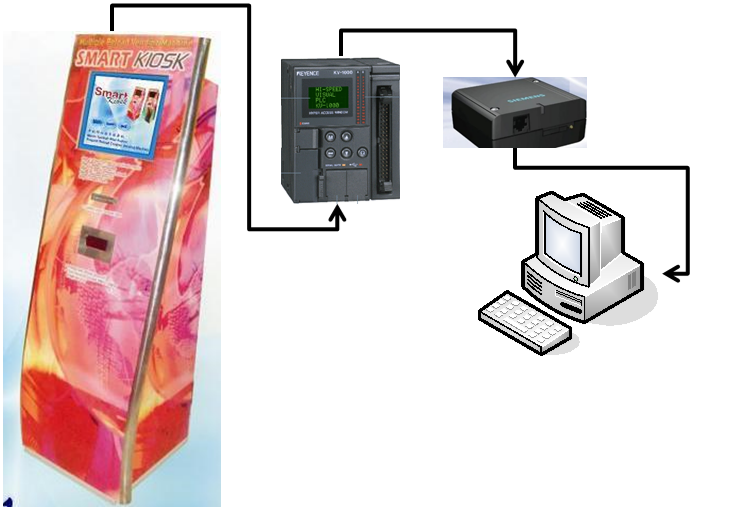

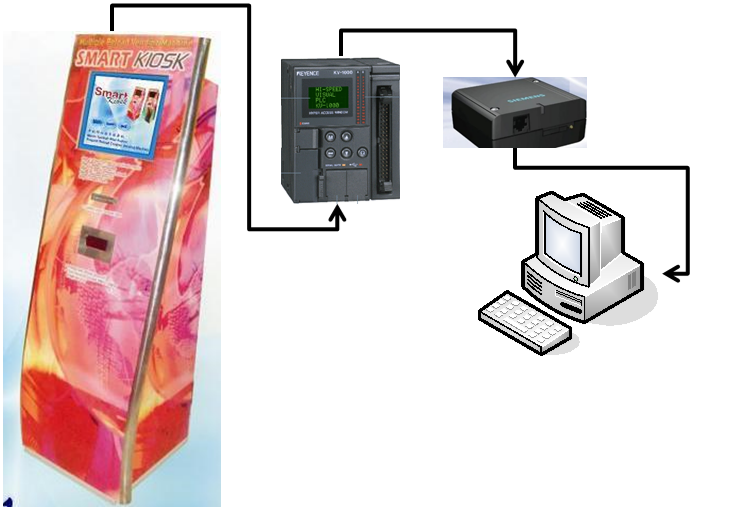

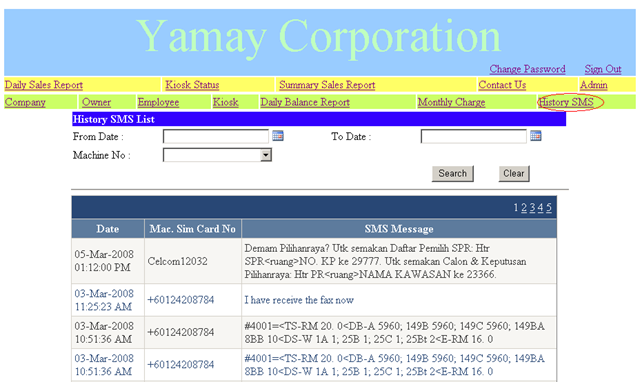

SMS-BASED KIOSK SALES SOLUTION

Show Case: Kiosk Sales Report Automation

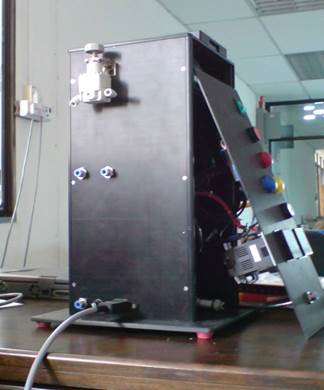

MACHINES CONVERSION AND UPGRADING

(Before) Plastic Trimmer Machine

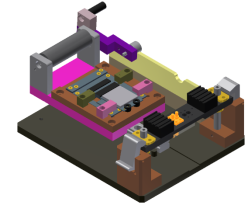

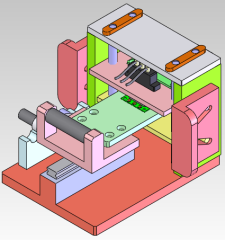

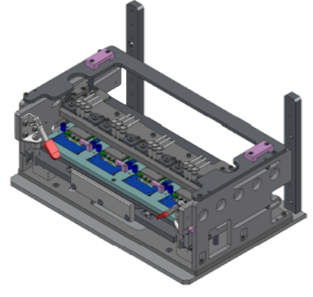

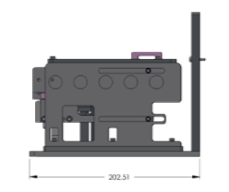

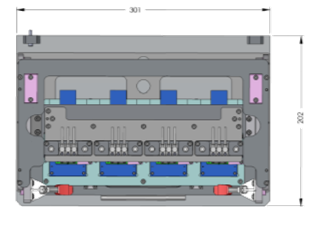

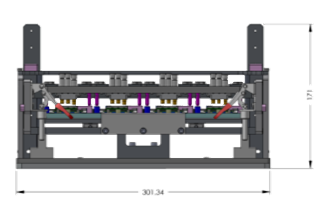

SEMI AUTOMATED SCREWING FIXTURE WITH DATA AUTOMATION

Semi Automated Screwing Fixture with Data Automation

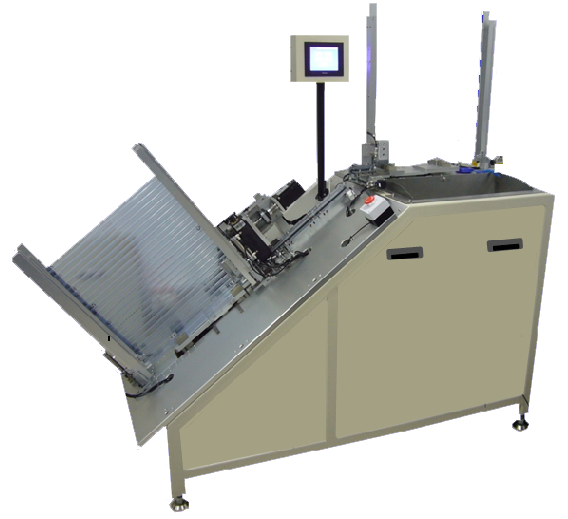

AUTOMATED STACKER

Automated Stacker

AUTOMATED WIRE DRESSER

Automated Wire Dresser

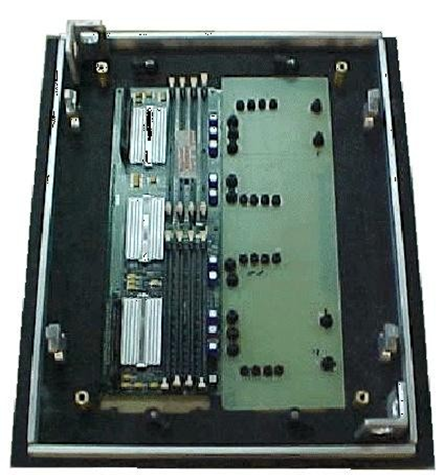

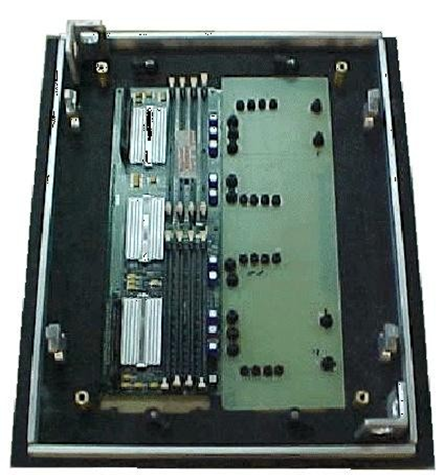

ELECTRICAL PANEL WIRING

Electrical Panel Wiring

WAFER INSPECTION SYSTEM

High-resolution and high-precision X-Y table Capable of handling 12” wafer Window platform with user-defined specifications Built-in calibration feature Auto-generation of GR&R report Library based uploading for different types of die Automated defect classification Wafer map creation/updates of loaded wafer map Optional inking capability for defect dies Statistical descriptive analysis of defects

AUTOMATED INSPECTION SYSTEM

Input: un-inspected wafer in cassette form Output: inspected wafer in cassette form

- Auto loader/unloader for wafer frame - Capable of handling up to 12” wafer - Window platform with user-defined specifications - Built-in calibration feature - Library based uploading for different types of die - Automated defect classification - Wafer map creation/updates of loaded wafer map - Optional inking capability for defect dies - Statistical descriptive analysis of defects

DIE/WIRE INSPECTION HANDLER

Input: leadframe/board form Output: leadframe/board form

- High-resolution and high-precision X-Y table - Multiple inspection stations - Auto marking for rejects - Micro defect inspection of up to 5 micron - Window platform with user-defined specifications - Built-in calibration feature - Auto-generation of GR&R report - Library based uploading for different types of die

- Orientation check - Device check - Centering position/offset inspection - Silver epoxy coverage inspection - Wire loop height measurement - Wire bond inspection e.g. sagging wire, missing bond, off pad etc

LASER MARKING HANDLER

Input: tray form / leadframe form Output: tray form / leadframe form

- Auto loader/unloader for input/output - Servo-driven linear X table - Multi-tasking PC-based controller - Antistatic brush (optional)

- QFN, DFN, MLP, QFP, CSP, BGA, VSOJ, etc

- Position feedback - Orientation check - Double Mark inspection - Package type confirmation - Marking Quality Inspection

INKJET MARKING HANDLER

Input: tube form Output: tube form

- Auto loader/unloader for input/output - Servo-driven linear X table - Multi-tasking PLC-based controller - Orientation inspection (optional)

- Seven Segment Display, QFN, DFN, MLP, QFP, CSP, BGA, VSOJ, etc.

- Position feedback

- Orientation check

- Double Mark inspection

- Package type confirmation

COMPONENT INSERT HANDLER

Input: loosen form/tube Output: tube form

- Multiple component handling - Teflon claw to avoid cosmetic rejects - Multi-tasking PC-based controller

- Mainly for component assembly

- Marking inspection

FLIP & ATTACH HANDLER

Input: reel form Output: tray form

- Servo-driven de-tape module - High speed flipper - Rotary pick-&-place method - Multi-tasking PC-based controller - Close-loop place positioning feedback

- QFN, MLP, QFP, SSOP, MSOP, TSSOP, VSOJ, D2PAK, D-PAK, SO, SOL, SOJ, SOT, SC, SOIC, LED, etc.

- Position inspection - Orientation check - Glue inspection - Package inspection

GRAVITY FEED TEST HANDLER

Input: tube Output: tube/bin

- Multiple bin output - Single/double-stack tube unloader - Multi-tasking PC-based controller - Poka yoke concept for sorting - Dynamic binning option

- LED - DIP, PDIP, TO - SOIC, SSOP, MSOP, QSOP, TSSOP - D2PAK, D-PAK, SO, SOL, SOJ, SOP - QFN/MLP

- Mark inspection - Package dimension check - Package cosmetic inspection

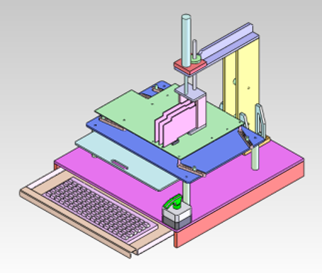

CARTESIAN TEST HANDLER

Input: tray form Output: tray form

- Auto loader/unloader for input/output trays - Servo-driven linear XY pick and place system - Multi-tasking PC-based controller - Gang test (optional) - Fine pitch probing

- QFN, DFN, MLP, QFP, CSP, BGA, VSOJ, etc

- Position inspection - Orientation check - Mark inspection - 5-side inspection - Pad inspection - Package inspection - In-pocket inspection

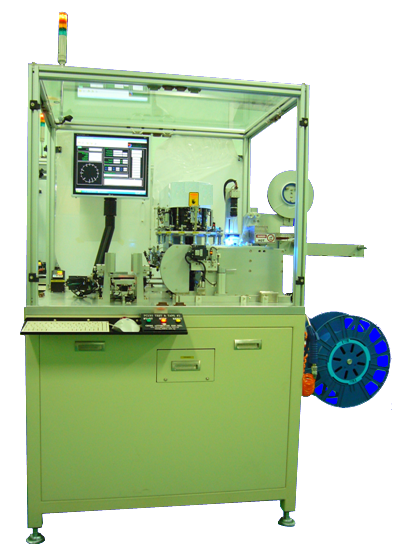

TEST & TAPE HANDLER

Input: tray form/loose form/tube form Output: tape & reel

- Rotary pick and place system - Auto loader/unloader for input trays - Multiple test stations - Multi-tasking PC-based controller - Programmable leader & trailer

- QFN, MLP, QFP, SSOP, MSOP, TSSOP, VSOJ - D2PAK, D-PAK, SO, SOL, SOJ, SOT, SC, SOIC - LED

- Orientation check - Mark inspection - Lead co-planarity inspection - In-pocket inspection

TAPE & REEL HANDLER

Input: tray form/loose form/tube form Output: tape & reel

- Rotary pick and place system - Auto loader/unloader for input trays - Multi-tasking PC-based controller - Programmable leader & trailer

- QFN, DFN, MLP, QFP, CSP, BGA, VSOJ, etc. - D2PAK, D-PAK, SO, SOL, SOJ, SOT, SC, SOIC - LED

- Orientation check - Mark inspection - Lead co-planarity inspection - In-pocket inspection

TEST & TAPE HANDLER

Input: loose form Output: loose form / tape & reel

- Rotary pick and place system - Multiple test stations - Multiple tape and reel modules (optional) - Multi-tasking PC-based controller - Programmable leader & trailer

- QFN, MLP, QFP, SSOP, MSOP, TSSOP, VSOJ - D2PAK, D-PAK, SO, SOL, SOJ, SOT, SC, SOIC - LED

- Orientation check - Mark inspection - Lead co-planarity inspection - In-pocket inspection

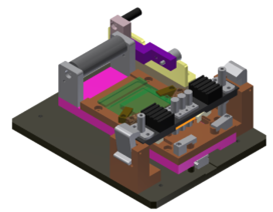

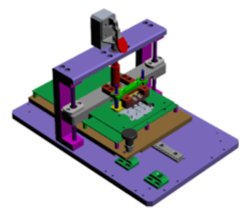

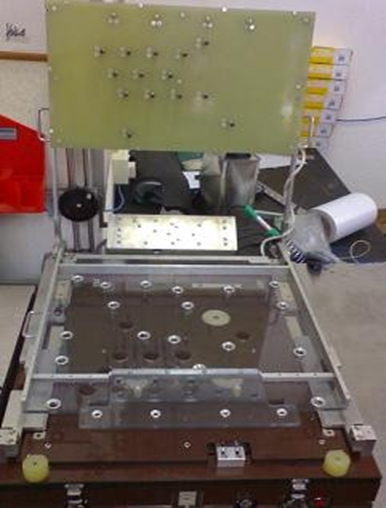

SEMICON (ELECTRONICS)- MANUAL TEST FIXTURE

HMC Manual Fixture

TEST FIXTURE

Test Fixture

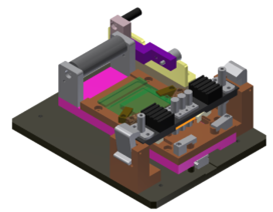

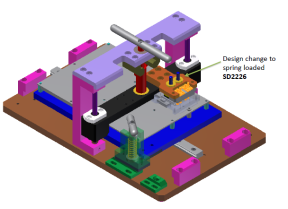

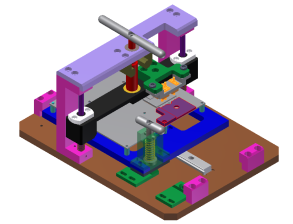

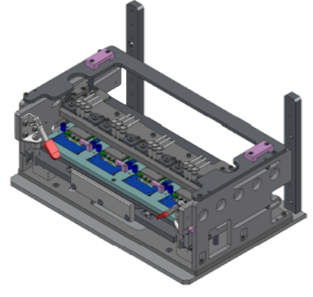

SEMICON (ELECTRONICS)- GANGed (4) INSERTION FIXTURE

GANGed (4) Insertion Fixture

WAVE PALLET

Wave Pallet

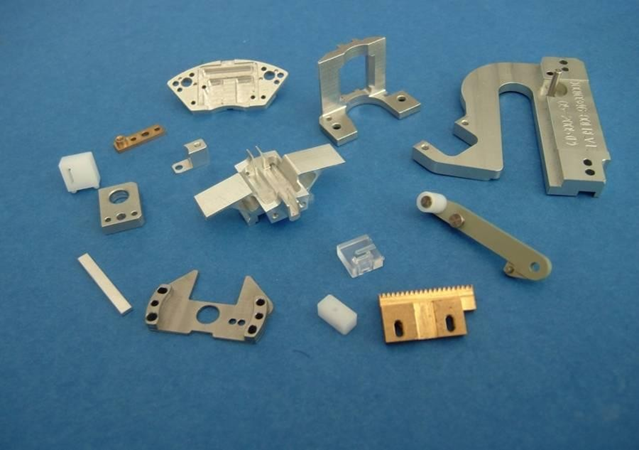

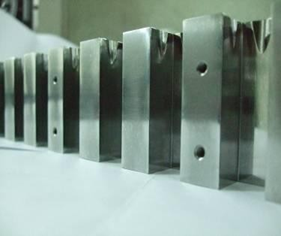

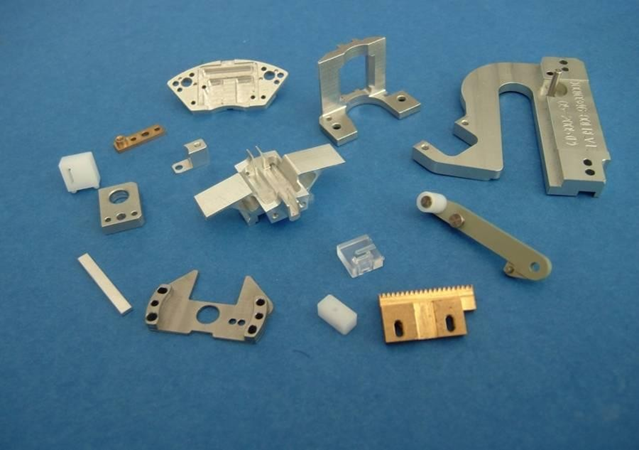

PRECISION CNC MACHINING PARTS

CNC Milling